Disclaimer: As an Amazon affiliate, I may earn a small percentage from qualifying purchases. This is at no extra cost to you. Learn more here.

If you are an experienced machinist, who has worked with both machines, then the difference between a lathe vs milling machine is obvious.

But new wood turners are often confused about the differences between the two and which one will be suitable for them. So if you want to know the difference, I’m going to spell it out to you loud and clear:

The main difference between a lathe and a milling machine is the technique. With a lathe, the workpiece spins while the blade stays still. Whereas with a milling machine, the blade rotates and the workpiece stays still.

You can also have a combination of lathe and milling machine. Here is my recent article about combo lathes and mills.

Of course, that is not the only differece between a benchtop metal lathe and a benchtop milling machine.

For a full understanding you could read my comprehensive articles, what is a lathe and what is a milling machine.

Or, if you just want a quick overview, keep reading!

Definitions

Before we get into the differences, first learn about both of them.

Lathe Machine: As said in our earlier article, the Lathe machine is called the mother of all machines. It is the most versatile and widely used machine all over the world.

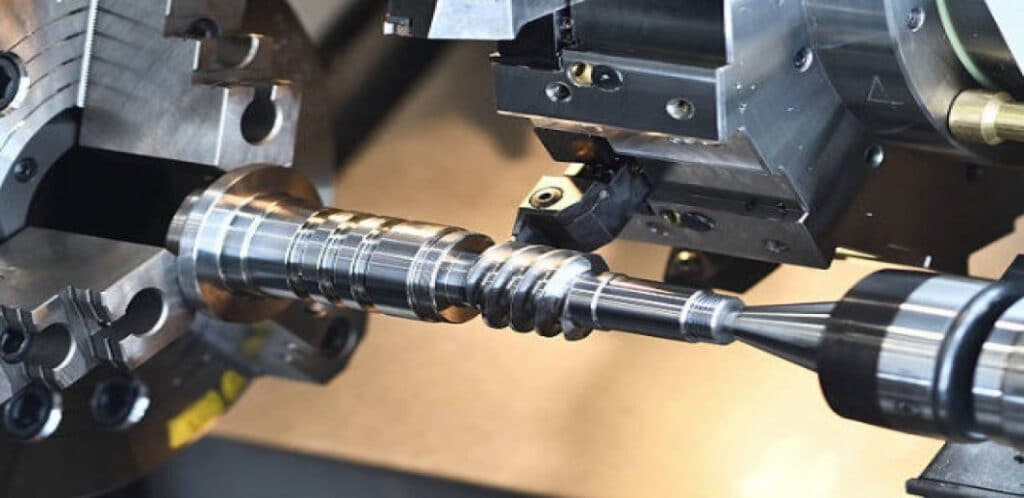

This machine rotates the workpiece on its axis to do a variety of operations like cutting, knurling, facing, etc. This one is a working wonder and can even work with both metal and wood.

Milling Machine: In a milling machine, cutters rotate to reduce material from the object to give it the desired shape. It is nowadays one of the most commonly used machines in industries and factories to make products of different sizes and shapes.

The Difference in The Working Method

Both machines can be differentiated with respect to their working method which is opposite to each other.

Lathe machine: The cutting tools stay stationary, and the metal or wood object is rotated to make various shapes. The chuck on the headstock holds the workpiece and rotates it continuously, and the tool holder holds the cutting tool which is tightened really carefully so that it can’t move.

Milling Machine: On the other hand, in the milling machine, the cutter is placed on a spindle or arbor, and it can rotate at high speed. Without rotating, the cutter has no other movement. The workpiece is held in the table of the machine. The movement of the table controls the feed of the workpiece.

When the workpiece is advanced towards the cutter, the cutter cuts, and the desired shape is produced on the object.

What are They Used for?

The lathe and milling machines can be used for a variety of operations:

Lathe Machine

- Turning

- Thread Cutting

- Facing

- Counterboring

- Boring

- Drilling

- Reaming

- Spot Facing

- Sanding

- Cutting

- Knurling

- Chamfering

Milling Machine

- Facing

- Side milling

- Plain milling

- Sawmilling

- Milling key ways, Grooves, and slots

- Threading

- Straddle milling

- Gang milling

- Form milling

- Helical milling

Variations of The Machines

Let’s now talk about the varieties of these two.

Lathe Machine

- Speed lathe/Wood Lathe

- Engine lathe

- Capstan and Turret lathe

- Tool-Room lathe

- Special Purpose lathe. They can be divided into several types:

- Wheel Lathe

- Bench Type Jewelers Lathe

- Automatic Lathe

- Crankshaft Lathe

- Vertical Lathe

- CNC Lathe

Milling Machine

- Horizontal Milling machine

- Vertical Milling machine

- Knee-Type Milling machine

- Ram-Type Milling machine

- Planner type Milling machine

- Manufacturing or Bed-Type Milling machine

- CNC Milling machine

The Differences in Cutting Tools

Lathe Machine

- In a lathe, the primary tool used is known as an insert cutter.

- It has a tip that can be removed.

- This will help you to cut and shape things.

Milling Machine

- However, when it comes to milling machines, insert cutter is not a common feature. In this case, the end mill is the most popular option.

- It can be operated at a different speed, which can be very helpful to you.

Things to Consider While Going for One

Lathe Machine: Suppose you want to cut a material that is cylindrical in shape, it’s better for you to choose a lathe vs milling machine. It will help you to do the job more precisely, and cutting will be easier. These two articles are to help you choose the quality wood lathe or metal lathe.

Milling Machine: Besides, while drilling holes, you can only drill at the center of the object by the lathe. But using a milling machine, you can make off-center holes as well as straight cuts also. If you want to make angled cuts and intend to work on noncylindrical materials, then it would be wise to go for a milling machine.

Conclusion

To be a good machinist, you need to have a good machine that can pave you the path. And purchasing a machine according to your needs is also an important task.

There are subtle, but lots of differences present between a lathe vs milling machine which lots of people don’t understand or know.

We’ve tried to cover all the related differences between them so that it becomes easier for you to differentiate between them. Hope this helps you.

If you’d like to know more about lathes or milling machines you can check out some other articles on my site, including what is a lathe? and what is a milling machine?