There are several lathe chuck mounting methods. Unless you are a pro at using a lathe, it’s normal for you to face some problems with a lathe while mounting chucks, especially on a benchtop metal lathe. Some people fail to mount a chuck properly after several attempts.

Well, that’s because they don’t have the proper direction. However, that’s a problem you won’t have to face again. That’s because, in this article, I am going to discuss different types of lathe chucks and their mounting methods.

Now, there are three types of mounting methods. And it’s important to know about all of them. I will try to explain the procedures in the simplest manner.

1. Drill Chucks Mounting

Drill chucks are the easiest to mount. You won’t have to go through much trouble to mount these chucks.

All you need is a vise and a hammer. So, how are you going to mount it? Well, you need to use either heat or cold in this process. I prefer heat. Any reason? Yes, it takes less time. However, some people do prefer the cooling process.

If you are in favor of heat like us, then you need a heat gun or blow torches. However, if you like the cooling process, a kitchen freezer will be required.

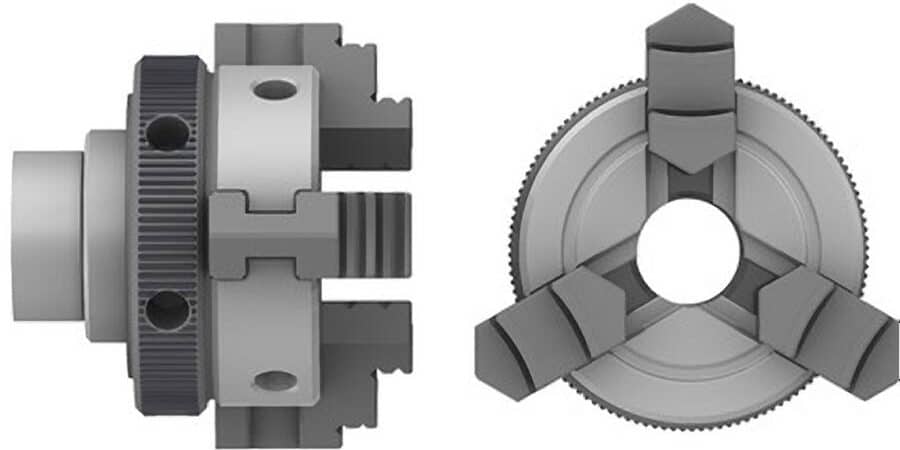

2. Jawed Chucks Mounting

Now there are various mounting methods for jawed chucks. Let’s talk about some of them.

Threaded Spindle Nose

The backplate will get involved in this process. The backplate must be threaded. You need to attach it to the threaded spindle nose. Though the process is straightforward, it will consume a lot of your time.

I think it’s not worth your effort and time. That’s because there are better alternatives available to allow you to do things in a much easier way and in a much shorter time.

However, since it’s a pretty old method that had been in use for a really long time, I thought it’s worth a mention.

Tapered Spindle Nose

If you ask us, I would say that it’s the best option for jawed chucks.

It will save you both time and effort. In this case, you will need to place the self-releasing taper on the male taper. The process significantly improves the repeatability of the entire system.

Cam Lock Spindle Nose

It’s another effective method for mounting the chuck. However, to be honest, it’s just a variation of the tampered spindle nose method. In this method, you will need to press the chuck against the taper.

Lately, the process has gotten quite popular for mounting jawed chucks. So, unless you have made up your mind, I urge you to give this method a try.

3. Collet Chucks Mounting

Collet chucks are a bit different than the other two. That doesn’t mean that you can’t apply the previously mentioned methods for mounting these types of chucks.

It may come to you as a surprise, but you can resort to the methods applicable for jawed and drill chucks.

That said, lathes that are run by collet chucks usually come with a dedicated system for chuck mounting. In simple words, those lathes come with a collet-closer system so that you can easily mount the chuck.

Now, the collet-closer system does not contain a backplate. Instead, it comes with a female taper. You might be wondering, what’s it for?

Well, this will be held by a matching male taper. Or there might be a sleeve. There’s also a hollow drawbar. It will go through the headstock and will reach the back.

You’ll see that the closing mechanism is set there. The mechanism is the reason why the collet can be opened and closed in such a short time.

Related article:

Recommended 4jaw, 3jaw and drill Lathe Chucks

How to cut a taper on a lathe.

Lathe cutting tool setting up process.

Conclusion

Now, you have a solid idea about the three types of lathe chuck mounting methods. But I’d like to share a word of caution. You see, the chuck must be mounted in the right way.

Otherwise, it might bring trouble for you and your machine. And it would be wise to apply the methods for the intended chucks.

Nevertheless, if you follow the instructions correctly, there’s no reason you should get into trouble. However, if you do, let us know in the comments section.

I’ll be more than happy to help.