Disclaimer: As an Amazon affiliate, I may earn a small percentage from qualifying purchases. This is at no extra cost to you. Learn more here.

Boring mills are a type of machinery typically used to enlarge holes that already exist. There are two main kinds: the vertical and the horizontal boring mill.

Aside from modifying these holes, they are also useful for drilling, grinding, and other applications, similar to a vertical lathe machine. They provide accuracy and efficiency.

I will provide you with more helpful information on this type of equipment in this article!

Key Takeaways:

- A boring mill is usually used to modify the size of existing holes using a cutter.

- It has two main categories: vertical and horizontal.

- The use of boring mills offers many advantages, such as increased precision and productivity.

How Does Boring On a Mill Work? The Full Process

As you probably know, there are two types of boring machines: vertical and horizontal boring mills. They mainly differ in orientation and whether the boring heads remain stationary.

Check out how each works below!

1.) Boring With a Horizontal Boring Mill

With a horizontal boring mill, the boring bar rotates, and the workpiece is secured to the table. Here is my basic guide to using one:

- Mount the workpiece onto the milling table, making sure the workpiece sits on the correct spot on the horizontal axis and vertical axis.

- Center the cutting tool over the hole to be bored, and secure with a chuck.

- Start the spindle and feed the cutting tool into the hole.

- Slowly insert the boring head, applying sufficient cutting pressure to remove material.

- Stop the feed and retract the boring head once the desired extent is reached.

- Repeat this process, increasing the diameter of the hole until the preferred size is achieved. Check progress with a dial indicator.

- Remove the workpiece and inspect the finished product.

- Repeat the process as needed to achieve the desired result.

2.) Boring With a Vertical Boring Mill

When working with vertical mill machinery, the workpiece rotates under the tool for cutting. Generally, here’s how I suggest you go about it:

- Mount the workpiece onto the spindle.

- Center the cutting edge over the hole to be bored.

- Start the spindle and feed the cutter into the workpiece.

- Slowly insert the cutter, applying sufficient cutting pressure to increase diameter.

- Stop the feed and retract the cutter once the desired extent is reached.

- Repeat this process, gradually increasing the size of the hole until the preferred size is achieved. Check progress with a dial indicator.

- Remove the workpiece and inspect the finished bore.

- Repeat the process as needed to achieve desired result.

Tips for Operating a Milling Machine

Whether you’re operating a vertical or horizontal boring mill, here are some helpful tips:

- Check the angle of the cutting tool

- Use a screw to secure the workpiece on the table

- Center the tool over the workpiece for precision

- Regularly check for proper alignment of the tool and workpiece center.

- Select the correct insert for the job

- Regularly inspect the equipment for wear

- Ensure the work-piece is stationary during the operation

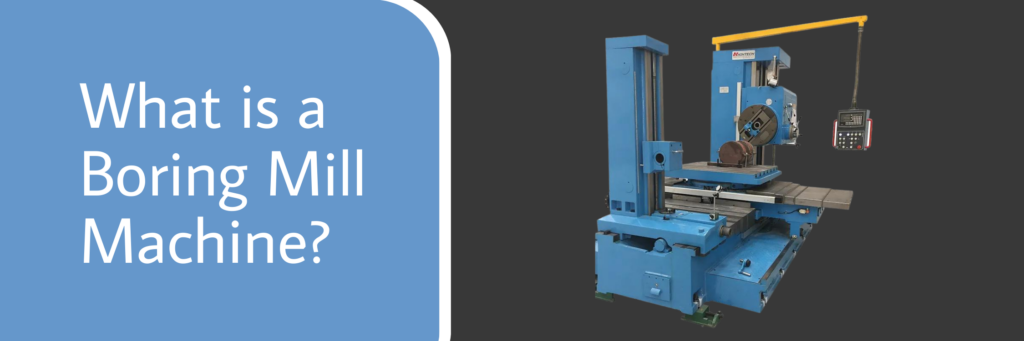

What is a Boring Mill Machine?

A boring mill machine is an industrial machine generally used to enlarge holes in various materials.

Like lathes, It uses a cutting tool, like a drill or boring bar, to remove material from the surface of the workpiece and expand the hole.

The cutting tool is attached to a spindle that rotates and can move along different axes to modify this hole. The workpiece is secured in place and rotated by the machine’s chuck.

Boring mill machines come in different types, including horizontal and vertical boring mills.

The main advantage of using a boring mill machine is that it can produce precise and accurate holes, saving time and money compared to other machine tools.

A boring mill machine is highly specialized equipment known for its efficiency and productivity.

Boring Mills vs. Lathes

Lathes and boring mills are both important machinery in manufacturing but have different functions and uses.

- Lathes are generally used for shaping and cutting materials into circular or cylindrical shapes.

- On the other hand, boring mills are typically used for enlarging and refining existing holes.

Boring mills generally have a larger and more complex structure than lathes and can handle larger and heavier workpieces than lathe machines.

What Are Boring Mills Used For?

Boring mills are usually used in manufacturing to make existing holes bigger.

They are used to create, modify, or repair parts for things like engines, aircraft, and other machines. Boring mills are good at making exact holes.

Boring machines can also be a valuable tool outside of the manufacturing industry.

An example is when they use a milling machine in construction to adjust the hole size of pipes and ducts.

Boring mills are versatile pieces of machinery that can be very useful in the right hands.

Benefits of Boring Milling Machines

Boring mill machines offer several advantages, including:

- Precise and accurate holes. Boring mill machines greatly minimize tool deflection, delivering precision of the exact desired size, shape, and depth of each hole.

- Improved quality. Boring mill machines produce smoother surfaces, even with tight tolerance, than other methods, such as drilling with a handheld drill.

- Time-saving. A milling machine offers cutting speed that helps increase productivity.

- Increased capacity. Boring mill machines can easily work with a larger diameter, making them useful for larger workpieces or specific functions.

- Versatility: Boring mill machinery can be used for various operations and can handle different types of materials.

Horizontal vs. Vertical Boring Mills

The main differences between horizontal and vertical boring mills lie in their orientation and operation form.

A horizontal boring mill operates with its spindle parallel to the ground and cutting tools mounted on a horizontal arbor.

Horizontal boring mills are often used for large and heavy workpieces as they allow for more efficient chip removal and better cutting action.

Then, a vertical mill operates with its spindle perpendicular to the ground and cutting tools mounted on a vertical spindle.

Vertical ones are often more compact horizontal boring mills; they are well-suited for smaller and lighter workpieces.

Boring Applications

CNC, or Computer Numerical Control, is a technology that uses computers to control machine tools like boring mills.

With this, the boring mill machine can deliver high accuracy (minimal tool deflection) and consistency and do multiple operations in a single setup. Manual intervention is also reduced.

Some operators say that a CNC boring mill machine is a specialized horizontal milling machine, while a vertical one is somewhat similar to a vertical lathe.

Frequently Asked Questions

Do you have more questions about the operation of boring mills? Here’s more info:

How is the Size of the Bore Determined on a Mill?

Its size is determined by the size of the cutter or insert used and the amount of material removed during each pass.

Regular measurements and adjustments should be made to ensure the final size meets the desired specifications.

What Are the Common Types of Boring Tools Used In a Mill?

Some common types include single-point cutting tools, indexable insert boring bars, adjustable boring bars, and boring heads.

Choosing which one depends on the type of material worked on, its size, and the level of accuracy you want to see.

What Are the Factors That Affect the Quality of Boring on a Mill?

This can be affected by several factors that may include:

- condition of the machinery

- choice of insert

- materials being machined

- cut speed and feed rate

- accuracy of tool alignment

A helpful tip would be to ensure that you center the spindle. You should also securely screw your workpiece to the table to prevent it from suddenly dislodging, for example.

Additionally, regular maintenance of the machinery is also crucial if you want consistent results.

Conclusion

Boring mills are used for enlarging holes by using cutting tools, like a drill or boring bar, attached to a spindle that rotates and moves along different axes to modify the hole.

They come in two main types: horizontal and vertical. Horizontal types are typically used for large workpieces, while vertical boring mills are more well-suited for smaller workpieces.

Boring mills offer several benefits, including precise holes, improved quality, time-saving, increased capacity, and versatility.