Disclaimer: As an Amazon affiliate, I may earn a small percentage from qualifying purchases. This is at no extra cost to you. Learn more here.

What are collets, and what are they used for? Are there different versions? Why do I need to use them when metalworking or woodworking?

In this guide to different types of collet, I’ll discuss what they are, how they function, and how and when they’re used.

Hopefully, at the end of this guide, you’ll have a better understanding of how they work.

Key Takeaways

- Collets utilize clamping pressure, forming a collar around the object they hold.

- All collet types operate using a tightening mechanism to induce static friction.

- The ER collet is the most popular and widely available clamping system.

- NOT ALL collets are compatible with most tools.

What is a Collet?

Collets or collet chucks are a type of chuck that holds a tool or workpiece in place. They come in different shapes and sizes and are used for different purposes.

They are ESSENTIAL PARTS of woodworking and metalworking, and each type of collet has its benefits and disadvantages inherent to its design.

A collet utilizes clamping pressure by forming a collar around a tool or object that you want to secure in place.

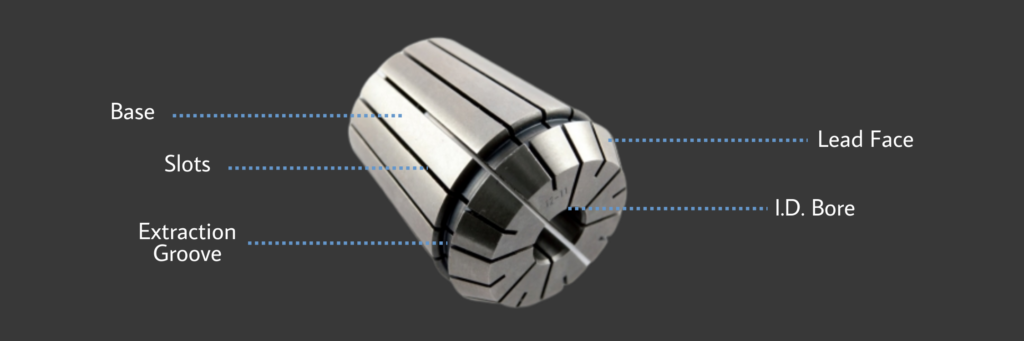

Parts of a Collet

They are similar to milling chucks used in milling machines because they have jaw chucks for work holding.

Typically, collet chucks can be adjusted via an adjustable wrench or screwdriver, depending on what collet type it is.

There are different types of jaw configurations that are used. The biggest difference is usually in the number of ways or cuts in the collet system.

Ultimately, the objective of how all collet types operate is to have ACCURATE ALIGNMENT between the tool and collet and clamp it firmly.

Types of Collet and Their Applications

Turners typically determine collet types based on their defining features, which distinguish them from other collets.

Here is a list of the main versions and their uses:

ER Collets

ER collets are used mainly in milling machines and are the INDUSTRY STANDARD when it comes to clamping systems for machining operations.

The ER collet chuck derived its name from the already established E-collet chuck (or soft collets) and combined it with technology from the development brand Rego-Fix.

The ADVANTAGE of the ER collet compared to the already established E-collet is the broader clamping usages, geometry, and spring design.

However, it’s meant to hold more cylindrical parts rather than square and hexagonal pieces of the soft collets.

They’re also split from both sides, which means that the ER collet shrinks and conforms to the tool or workpiece while retaining its cylindrical shape.

ER collets come in different sizes, from ER-8 to ER-50. Each series number indicates the receptacles tapered diameter size in millimeters.

It’s important to get the receptacles tapered diameter size right when getting a size.

TG Collets

TG collets are similar to ER collets in many ways, and its name stands for Tremendous Grip (TG) collet. These collets have a lower holding range, smaller overall size, and tighter holding pressure.

The MAIN USE for a TG collet is for holding carbide tools for milling, tapping, drilling, boring, and reaming operations.

TG collets are versatile clamping devices because of their higher holding force compared to ER collets.

DA Collets

The RDA or DA collets are short for double angle collets. This is because they’re split into two sides, similar to how an ER collet is.

DA collets are clamping systems suitable for broader clamping usages, EXCEPT for use with milling machines. This is because they can be prone to cracking.

5C Collet

This basic collet is usually split open three ways on one side and closed on the other. A hinge tightens and loosens the collet.

5C collets are made with a hollow cylinder shape, which makes them ideal for holding longer-stocked tools. They also have external and internal threads.

The inner cylindrical surface is tapered to allow for a tighter fit, too.

This collet system is ideal for lathes and mills for metalworking applications because of its simplicity and durability.

However, for larger or more weirdly shaped tools like square and hexagonal pieces, you may require specialty collets.

R8 Collet

R8 Collets are very similar to the 5C collets in how they work. They’re a STANDARD metalworking collet with one opening on one side that’s split three ways.

However, there is a drawbar to stop any object inserted from penetrating too deep into the tool. It doesn’t allow for the same penetration depth as s 5C collet.

The R8 collet also has a wider body and a more abrupt and sharp ending compared to the 5C, leading to a more narrow clamping range.

Autolock Collet

Autolock collets have a threaded locking system that locks the tool shank screws into the collet. The more the collet rotates, the tighter the lock of the centering pin on the cap taper.

They’re easy to use and very secure. However, they can only be used with shanks that match their tapper. These collet types are hand adjustable.

Although they’re NOT the most versatile collet chuck system in CNC machining, as they can only be used with specific tool shanks, they’re convenient.

AF Collet

AF collets, or Acura-Flex collets, have splits on both sides. This means AF collets have four ways in the front and rear.

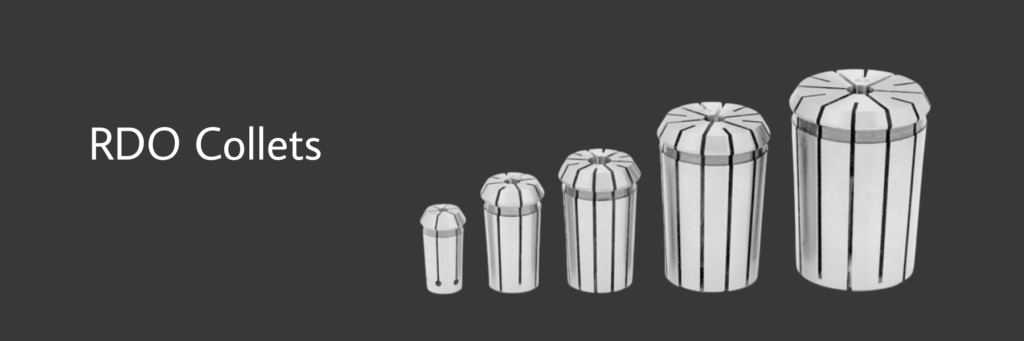

RDO Collet

RDO collets are also called ortlieb-style or full grip collets. They’re one of the MOST TRUSTED clamping systems for woodworking.

Watchmaker Collet

Watchmaker collets hold things like small watch gears on a watchmakers’ lathe. Some have waxed and cemented adapters to hold small objects.

Step Collet

Step collets are UNIQUE because of their flat and wide face. They can be machined to accommodate larger-diameter workpieces.

Morse Taper Collet

These morse taper collets are a VERSATILE collet chuck system that most people use in lathes, drill presses, and milling machines.

They’re versatile clamping devices with many tools and have readily available adapters to connect to other tools like ER collets.

Different Collet Configurations

Different types of collets also have varying configurations. They can also differ depending on the manufacturer’s design.

Make sure to pick up the collet configuration that fits your needs better!

Bore Configurations

Larger diameter, smaller diameter, hexagon, step collets, and inner conical are just some of the many configurations that shaped collets come in.

The bore is the shape of the opening of the collet. Therefore, these differently shaped collets have specific shapes that they conform to.

Some collets are better at holding different types of collets because of their shape, like the step-like internal clamp of step-bored collets.

DID YOU KNOW: There are some specialty collets called eccentric collets that are molded for holding specific tools. These will be the most trusted clamping systems for oddly shaped work tools.

Clamping Surface Configurations

You can get a collet in different clamping surface configurations. Some are smooth, while others have varying patterns of grooves or coatings to grip on machine tools for.

Collets with grooves like grip collets exert a HIGHER clamping force and static friction than those with smooth surfaces.

On the other hand, carbide-coated surfaces give the clamp a roughened holding surface.

Extended clamping surfaces, on the other hand, wraps more surface area around the tool, giving it more clamping force

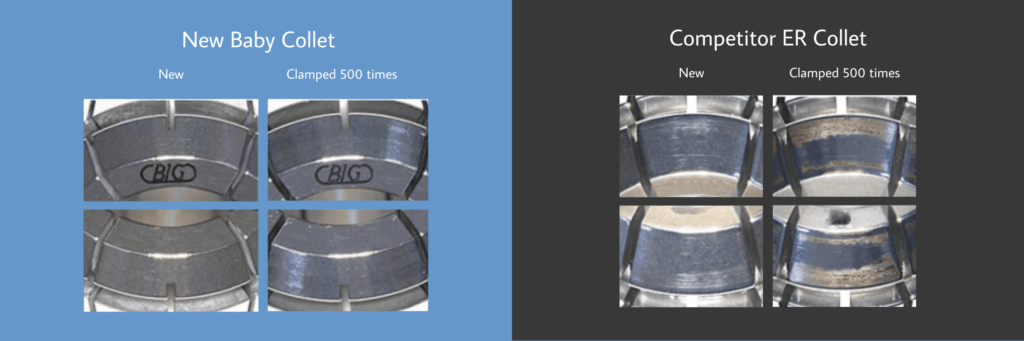

Wear Reduction Configurations

The inside of collets isn’t only different based on grooves. Many companies choose to add more coatings to make the inner cylindrical surface of the collet MORE DURABLE.

As you use the collet, the steady clamping pressure and constant clamping and de-clamping will cause wear. These coatings aim to reduce loss of grip.

Slot Configurations

The slots on the sides of the collet open and close to clamp on the tools being used. There are different configurations for this for more optimal and steady clamping pressure.

The system applies consistent clamping pressure while simultaneously preventing machined chips from lodging in the mechanism and interfering with collet operation.

Another one of the MOST IMPORTANT considerations you should have when buying a collet is slot configurations as it directly affects performance and longevity.

Slot Positions

Slot positions for a collet chuck are helpful in making sure that different shapes will fit into the collet chuck. Some examples are in front, in shaft, or in cone.

There’s also one slot position that has a flat surface on one side for alignment with another flat surface like a table. This is called an alignment surface slot position.

Insert Configurations

Insert configurations are one of the ways that a collet utilizes clamping pressure without wearing it out and NOT using coatings or grips.

Inserts are placed inside the collet to cover scratch-sensitive materials, both on the collet chuck and on the tool itself.

Then, instead of replacing the collet when it’s worn out, the user only needs to replace the inserts, which are a lot LESS COSTLY.

Plastic, aluminum, Permaglis, brass, bronze, and self-turning inserts are some of the options for insert configurations.

Miscellaneous Configurations

There are a few other configurations that are specialty collets for specific use cases in collet systems:

- Sealed – openings and sides are sealed to prevent machined chips from entering

- Coolant Sealed – prevent any leaked coolant to flow through a cutting tool

- Coolant Flushed – coolants flow through slits in the collet

- Emergency – user can customize the clamping force and bore diameter

These are only some of the many configurations that are intended for usage with certain tools and in certain work environments.

Collets for Metalworking

The standard metalworking collet needs to hold a round bar or tools, although you may need other shaped collets for other tasks or less typically machined tools.

ER Collets

These E collets are perfect to fit cylindrical parts like a round bar. They can fit to the end of a cutting tool or drill presses as long as they’re cylindrical enough.

Step Collet

Step collets can be used for the larger tools in woodworking that need to be clamped down and secured. This is because of their wide diameter.

Unlike E collets, they’re a lot MORE VERSATILE. This is because E collets are typically machined for a singular purpose or tool.

PRO TIP: To get accurate alignment on weirdly shaped tools, you may require specialty collets.

Collets for Woodworking

There are a few collet systems that are suitable for use with woodworking. Here are a few:

ER Collet

ER Collets are great clamping systems for woodworking. The ER collet chuck derived its name and design from the E collets, already popular at the time.

They can function as tool holders when the woodworker is busy.

For example, a cutting tool can’t always be in the woodworker’s hand. They need to be clamped down and secured somewhere.

It’s secured to the tool using a hexagonal collet nut, allowing it to be tightened or loosened to the motor arbor.

A motor arbor holds finishing products in place, while a hexagonal collet nut secures the whole thing in place.

RDO Collet

This is a great option for woodworking because of the increased grip capacity.

Frequently Asked Questions

After learning about the different collet types, you might still have more questions, so I’ve answered a bunch of them below:

What is a Collet Nut?

Collet chuck nuts are locks on ER collets. It’s located on the inside of an ER collet and locks it into place.

How are Collets Different than a Chuck?

A chuck tightens around an object, while collets use clamping pressure by forming a collar around the object.

What is a Router Collet?

Router collets are used in the router woodworking tool. They’re steel bored and matched to the router to help secure the bit in place as it rotates over 20,000 RPM.

How Are Standard Chucks and Spring Chucks Different?

Standard collet types have a back plate. Spring collet chucks have a hollow cylindrical design instead. This makes it easier to insert tools like wrenches.

Conclusion

Hopefully, you’ve learned more about how collets work, and about the different types of collets.

You should pick the one that suits your needs. For example, if you’re a woodworker, choose ER collets or RDO collets. If you’re a metalworker, choose ER collets or Step collets.

Good luck!